1) Sign up for a free Tinkercad account (http://tinkercad.com) and create a model of a form that you would like to prototype (3D-print). (Tinkercad has built-in tutorials; one of which you'll be able to find from the start-page.) Explore the software and play with it, see what you can do with it; see how far you can get your form look the way you want it to look like. Come up with an interesting idea and pursue it. Or maybe you want to build on some of the shapes others have uploaded to Tinkercad or Thingiverse (http://www.thingiverse.com/). Once you are satisfied, create a screenshot of it and upload it to your blog. - After finishing this assignment, please make an appointment with Sean in the next few weeks so you can print and enjoy the physical form. If you do this, please add a photograph of the printed 3D-form on your blog next to the screenshot.

Here is my "Welcome Home" sign with holes in the back so it can be hung!2) Research an artist who works with 3D printing creatively. Blog about it.

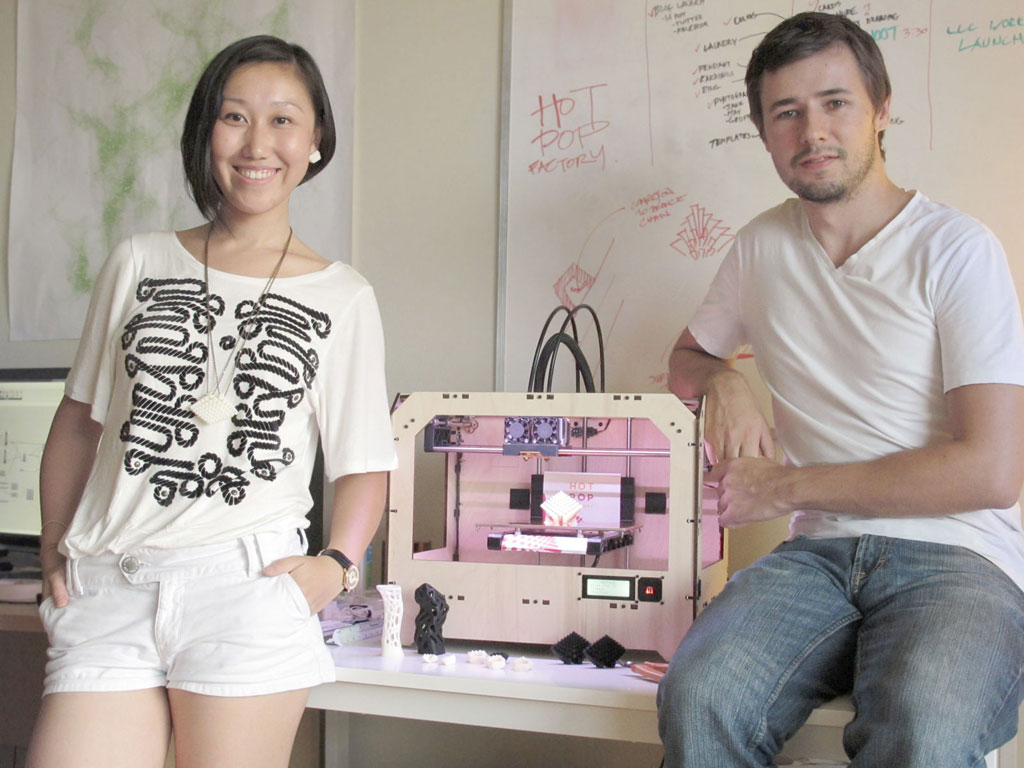

Hot Pop Factory

Hot Pop Factory is a new 3D printed jewelry company started by architects Matt Compeau and Bi-Ying Miao.

"For us, process is at the heart of it all. The idea of Iteration has been instilled in our brains since first year architecture school. With Hot Pop Factory, we are applying the same philosophies to a smaller scale - jewelry. For all the ideas that were too complex, expensive, impractical or just too wild to construct into buildings, we want to make into 3D Printed wearable ART"

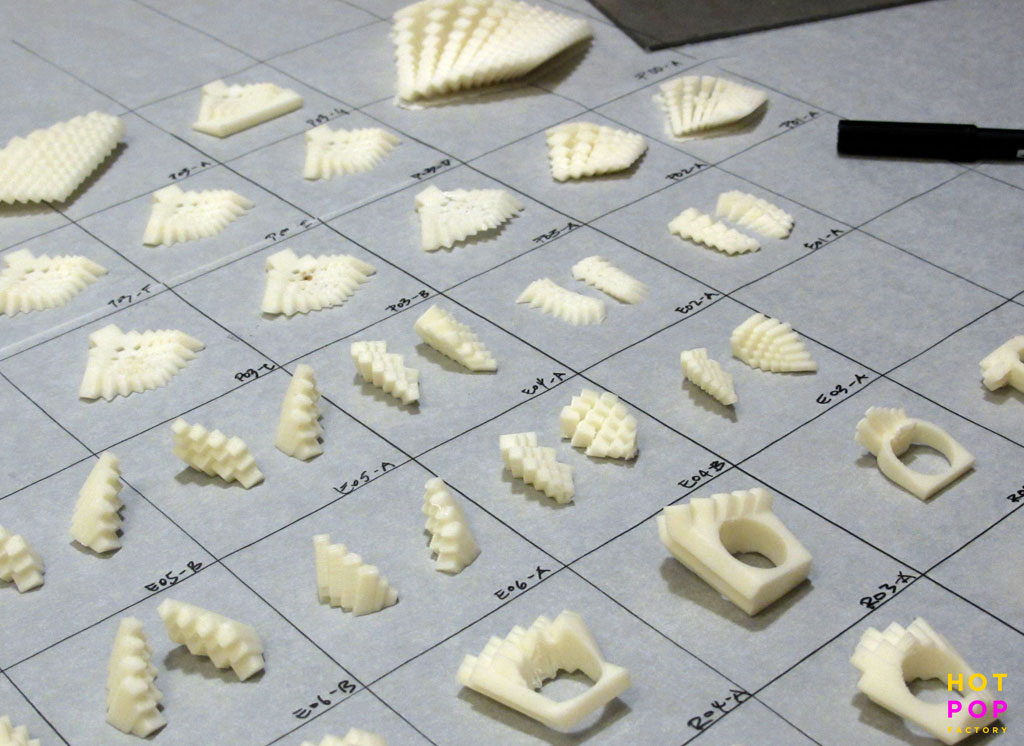

Each piece is created with computational design tools we use to design buildings, and fabricated with a Makerbot Replicator. Several prototypes of each piece were made before the designs were finalized.

"The evolution of these prototypes poignantly embodies our journey from curiosity to discovery. We let our high-tech tools guide us in developing the seed of an idea and allowing it to grow into a small business. These technologies have empowered us to take full control of our design process. The result is a unique collection that is entirely designed, developed and produced from our cozy apartment in Toronto. The best part, we can sip beers, watch movies, and rock out to our favorite tunes while doing it all."

Wilfried Vancraen

Wilfried Vancraen is a founder and CEO of Materialise. After finishing a Master's degree in Electro-Mechanical Engineering in 1985, Vancraen worked as a Research Engineer and Consultant at the Research Institute of the Belgian Metalworking Industry, which is where he first discovered 3D Printing. Passionate about this new technology and firm in his belief that it could help create a better and healthier world, he started Materialise in July 1990, where he remains CEO to this day. Materialise is a leader in Additive Manufacturing (also known as 3D Printing). Wilfried holds several patents related to the technical and medical applications of 3D Printing and remains committed to using the technology to make positive changes in people’s lives. In recognition of his work, he was awarded the RTAM/SME Industry Achievement Award in 2011, which is considered the highest honor in the 3D Printing industry.

The above images are from New York Fashion Week 2013 in which Materialise contributed to the making of the garments.

The above image is Daniel Widrig's The Art & Science of Supernatural Motion (2013) made out of resin using the 3D printing technology. Inspired by images of a figure accelerating and slowing through 3D space, Daniel transformed a series of digital photos into a hanging wall sculpture over 4 meters in length. However, the complex and intricate nature of the piece rendered it impossible to produce using traditional technologies. Having previously collaborated together on other projects, Daniel turned to Materialise to help him realize his vision.

Through its work with Additive Manufacturing (AM), also known in the popular media as 3D printing, Materialise is helping bring great ideas to life. It seeks to work with others to put great products aimed at niche markets directly into the marketplace as well as helping make the prototypes of products later manufactured by the millions. What’s more, through its software, Materialise enables others to do the same with their own AM equipment and services.

Materialise is also putting the power of Additive Manufacturing into the hands of everyday people. With an easy-to-use online service, now anyone can create a truly customized object, whether they are experts at computer modeling or beginners who are discovering 3D printing for the first time. We have also challenged some of the world’s top designers to use this technology in the creation of an award winning line of 3D printed objects available for sale worldwide…or from our own store in Brussels, the world’s first store dedicated to 3D printed design.

3) As you look back at our exploration of video, come up with 3 ideas how you would like to work with video in an art classroom. Describe these ideas briefly; and turn one of them into a lesson plan.

-make a seemingly one-take film similar to Justin Bieber's "Beauty and A Beat" MV (2012) by editing

-instead of taking a one-take vidoe, take multiple pictures and make a video using them

(e.g. still-picture animation including clay and paper animations)

-make a video/film using some sounds but no voice similar to "Paperman"

4) If you have chosen one or more photographs from the students of Augsburg University, please submit your response on the class-blog (see previous post). This is a separate assignment and not part of the grading but I warmly encourage you to participate in this beautiful expansion of our class and to have some fun with it.

|

| Photo I took in NYC |

|

| Photo taken in Germany |

|

| Photo taken in Germany |

|

| Photo I took in NYC |

Manhattan Theater; very funny.

ReplyDeleteJust wanted to take a minute to say that the 3d artists you've highlighted here are fantastic! All in all this was super illuminating and I feel like with this entry you're moving beyond just "art" and into "what can we do with this art" and I think that's a great way not only to approach 3D printing, but also any other media that we come across in the future!

ReplyDelete